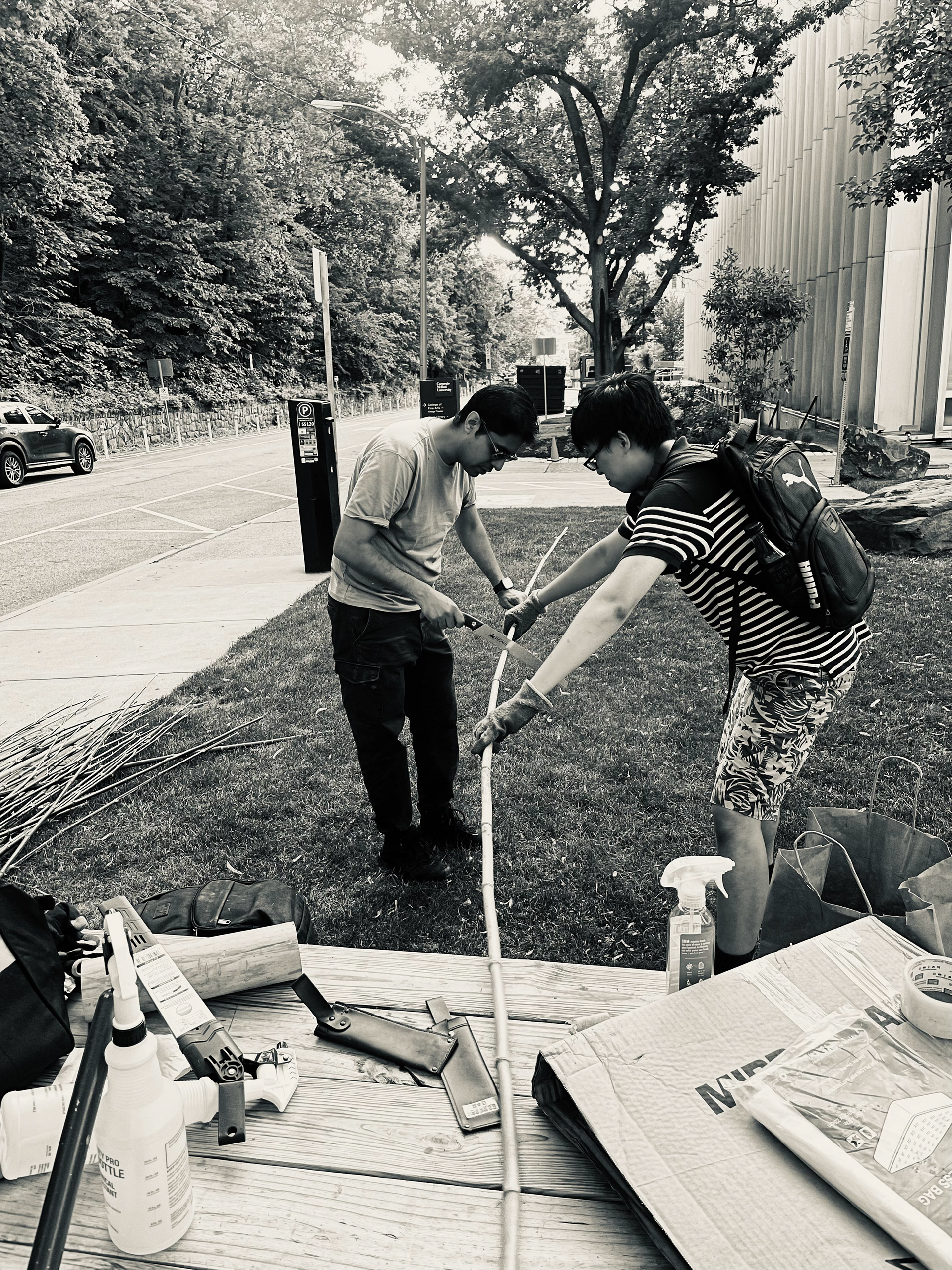

Every step of the fabrication process, ranging from material sourcing, material harvesting, digital fabrication preparation, and handcrafting, was completed by students under the guidance of their faculty advisor. With the material, students to make informed decisions on details, form, building and structural systems, and site positioning. Designing for both assembly and disassembly, students learn to source and repurpose materials on a local scale.

Multiple trips in cargo trucks, driven by students, to transport the material. Material was sourced from many places, including a contractor who built structural columns for local coal mines using bamboo and bamboo forest inside the City of Pittsburgh.

Students worked to design and fabricate the structural components such as the beams, columns, and hubs connecting the beams and columns.

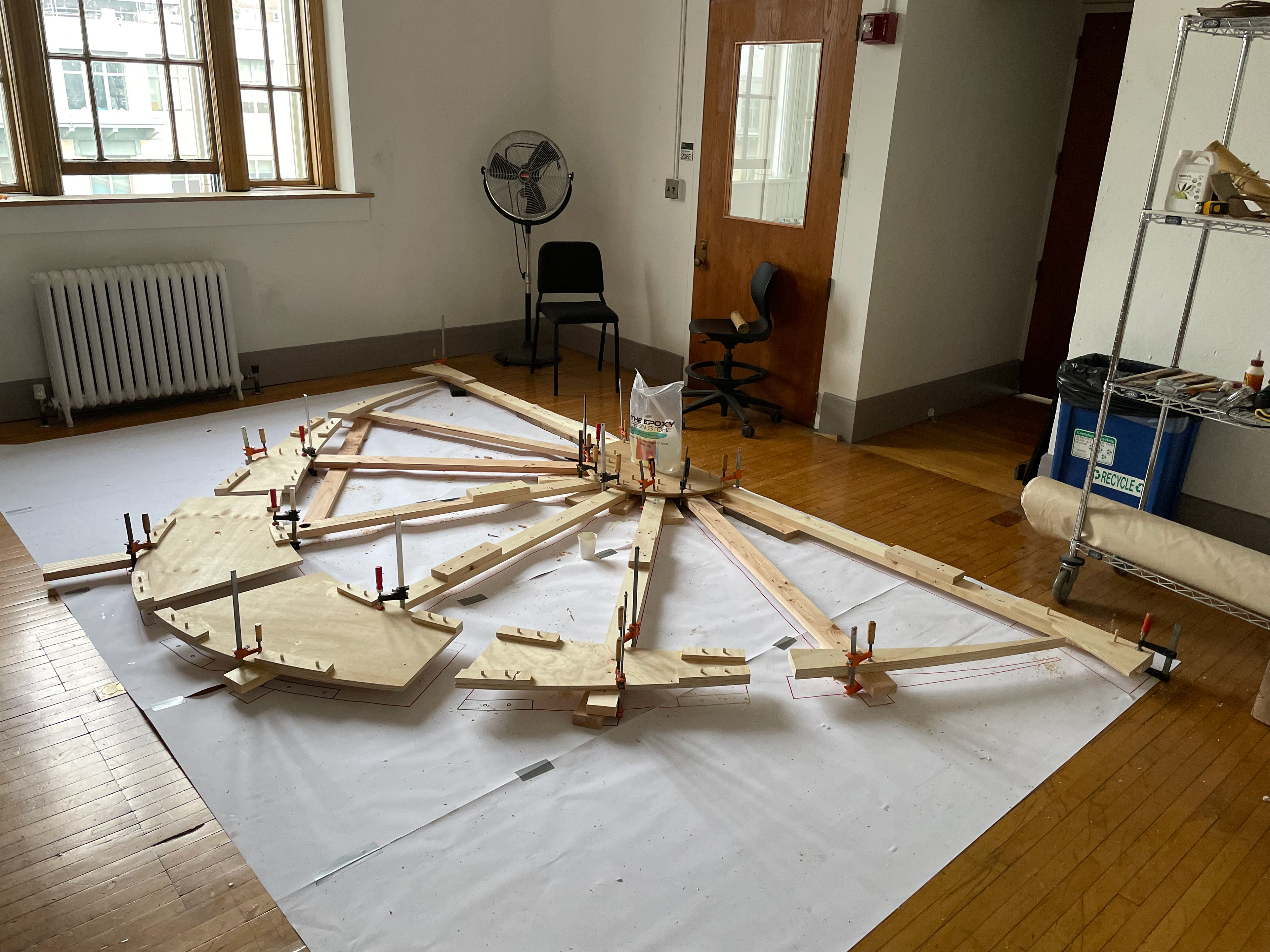

Arch Fabrication - Students designed and built a jig using CNC'ed plywood and then formed split bamboo pieces into the shape of the arch.

Jig for Forming Arches

Completed Arches

Arches formed on Jig